Gear Fixtures Expertise We Share

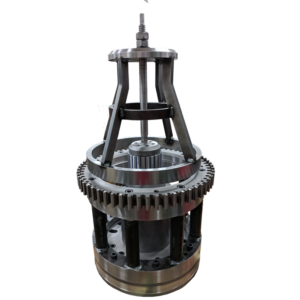

With over 74 years of designing and building gear fixtures, the shortest lead times in the industry, and a history of solving difficult workholding issues, Drewco is your solution for gear workholding.

Drewco provides a wide variety of solutions for your gear manufacturing needs.

We hold gears with bores as small as ¼ inch and gears as large as 8 feet in outside diameter.

We regularly design and build complete gear production packages, including:

Examples of Our Gear Fixtures

Hob and Grind Fixtures

Drewco designs hob fixtures to hold gear blanks securely, while the hob cutter generates the OD gear tooth profile. Gear grinding fixtures hold gears during the finish tooth grinding of OD gear profiles.

Drewco hob and grind fixture designs focus on:

- Meeting the needs of each individual customer application.

- Rigidity, repeatability and specific tolerancing.

- Addressing a family of part sizes with minimal changeover components.

Hob Arbors and Mandrels

Drewco’s workholding techniques can improve clamping force and make for more collet contraction. Drewco can accommodate a multitude of component diameters for greater adaptability.

Custom Cutter Adaptors

Shaping and skiving cutting tools are held in their machines by fixtures called cutter adapters. Customers come to Drewco for custom special cutter adapters that can position the cutting tool to hard-to-reach gear tooth areas.

Whether your part has internal or external teeth, Drewco can create special cutter adapters in various shapes and lengths for your applications.

Shaping and Skiving Fixtures

Shaping and skiving fixtures hold gear blanks for ID profile tooth cutting and for OD profiles that cannot be hobbed due to the gear’s configuration, machine, or cutter availability.

Our experience working with the skiving process, has allowed us to create accurate diaphragm chucks and secure collet chuck skiving fixtures resistant to the intrusion of fine skiving chips.

Tooth Milling Fixtures

In recent years, the practice of milling gear teeth has resulted in faster production. Working in coordination with machine tool builders and OEM’s our tooth milling fixtures, can address families of over 50 parts sizes on one fixture, from small to very large gears. Drewco fixtures are designed for maximum rigidity to handle the cutting force of tooth milling.

Gear Inspection Fixtures

Our history of making gear generation fixtures gives us a unique skill set to design and produce gear inspection fixtures. These between centered fixtures, can be collet center mandrels, hydraulic arbors, and pot fixtures. They can offer manual and automated clamping. Drewco’s double tapered XX style arbors have been performing in major OEM for over 40 years.

Additional Information Capabilities

We manufacture chucks to hold a variety of gear geometries including ID and OD splines that match specific gear forms, different shaped gears, like partial gears and gears with d-shaped bores.

We design our gear fixtures to:

- Address rigidity

- Increase cutting tool performance.

- Decrease run time.

- Reduce set up time.

- Reduce operator error.

- Consider flexibility to maximize fixture usage.

- Can include expandability for future parts.

We design fixturing for the full range of gear types.

- Bevel Gears

- Sun and planetary Gears

- Pinion Gears

- Spur Gear

- Helical Gears

- Splined Gears