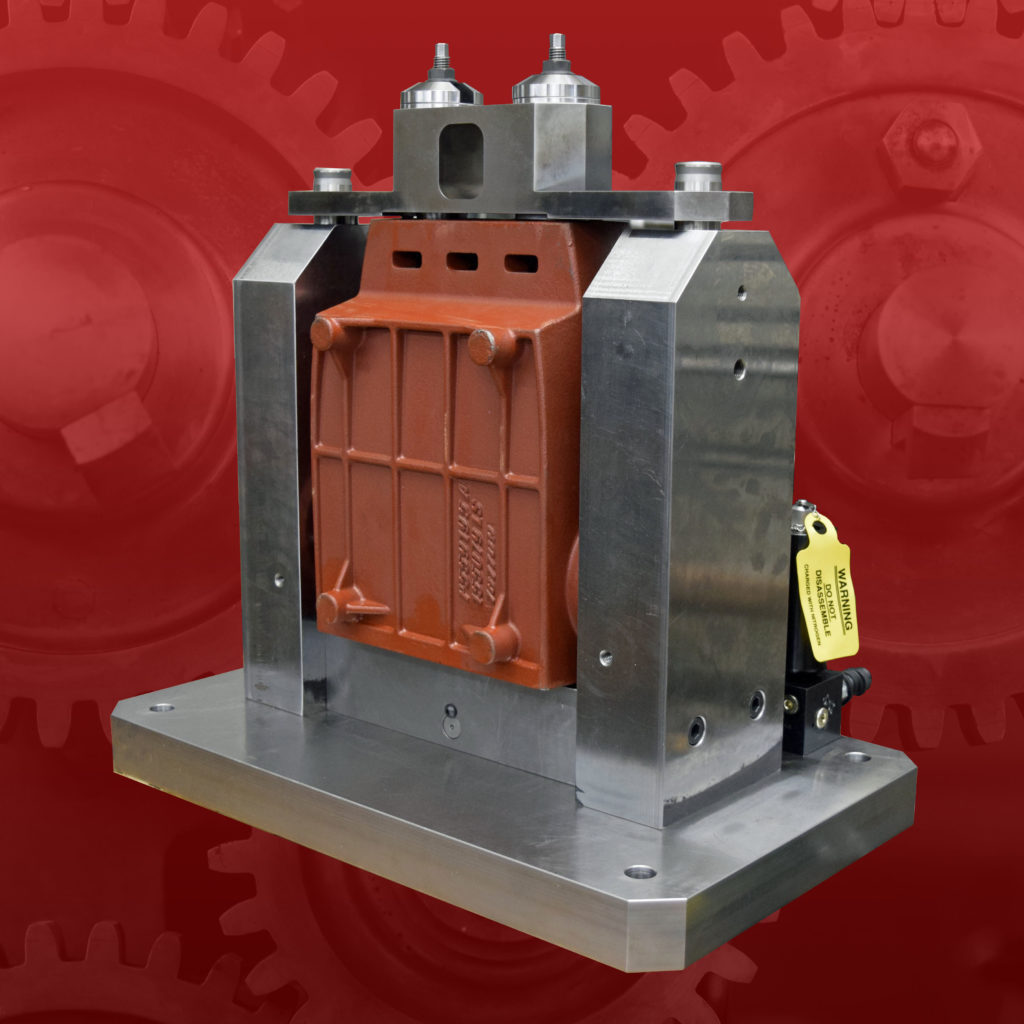

Machining Center Fixtures Milling Fixtures

Drewco is an experienced manufacturer of machining center fixtures, including individual hydraulic and pneumatic fixtures, and complete turnkey applications. Our fixtures are designed to maximize the production of machined parts, and our team of engineers can assess your project to ensure that the machined parts are stable and dimension tolerances are creating maximum efficiency.

Drewco fixtures can reduce process time, cycle time per part, and cost per part. Drewco design engineers can act as part of your production flow team.

Examples of Our Machining Center Fixtures

Drewco offers the following machining fixture workholding:

-Trunnion and Indexing Fixtures

Drewco can ensure longer uptime and increased capabilities for rotary table loading. We design to incorporate multiple part sizes and the production of more facets in a single operation.

-Tombstone Fixtures

Tombstone fixtures need to be agile and scalable. Drewco’s tombstone designs facilitate smoother installation, faster changeover, and more efficient coordination with automated systems.